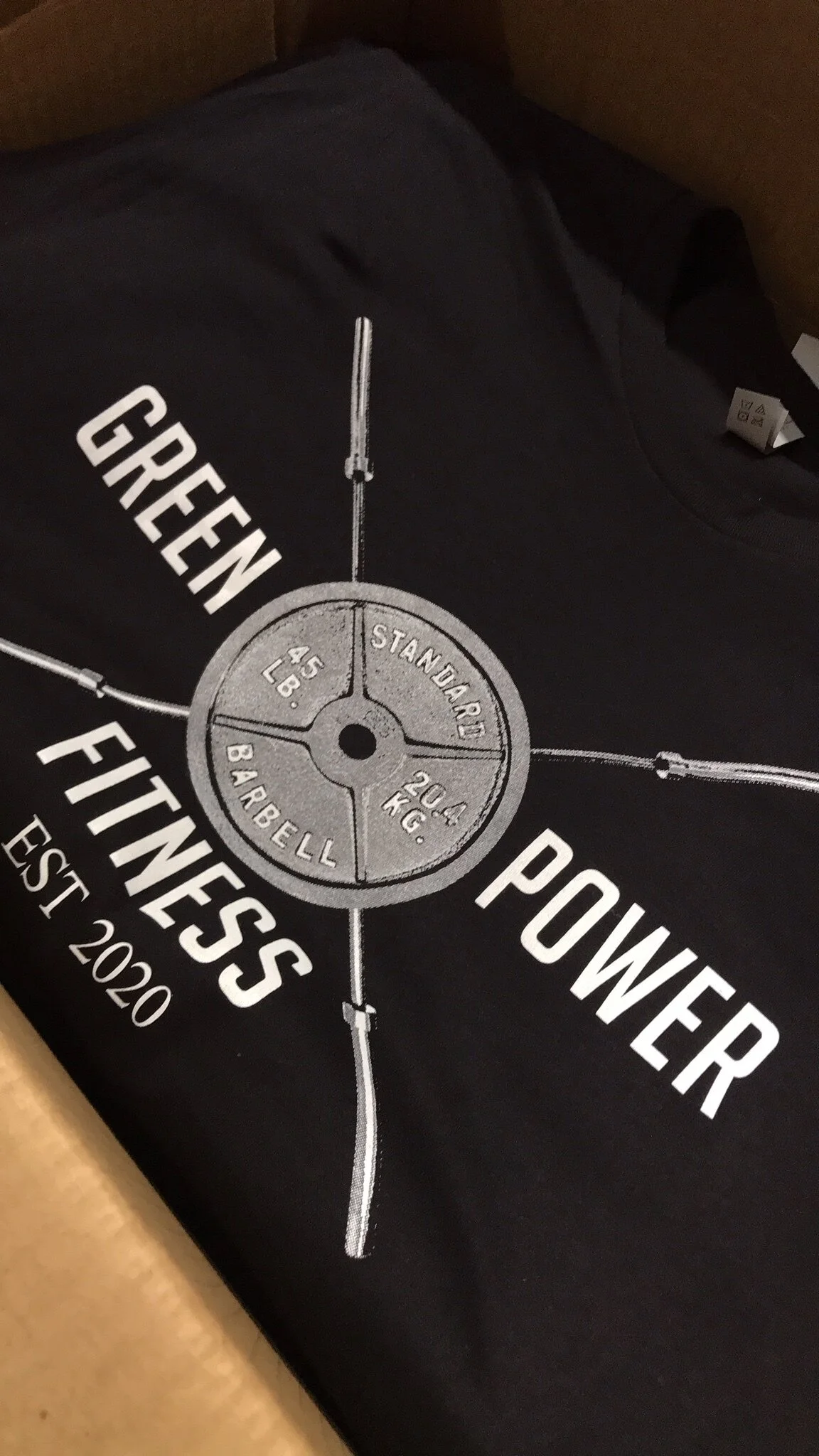

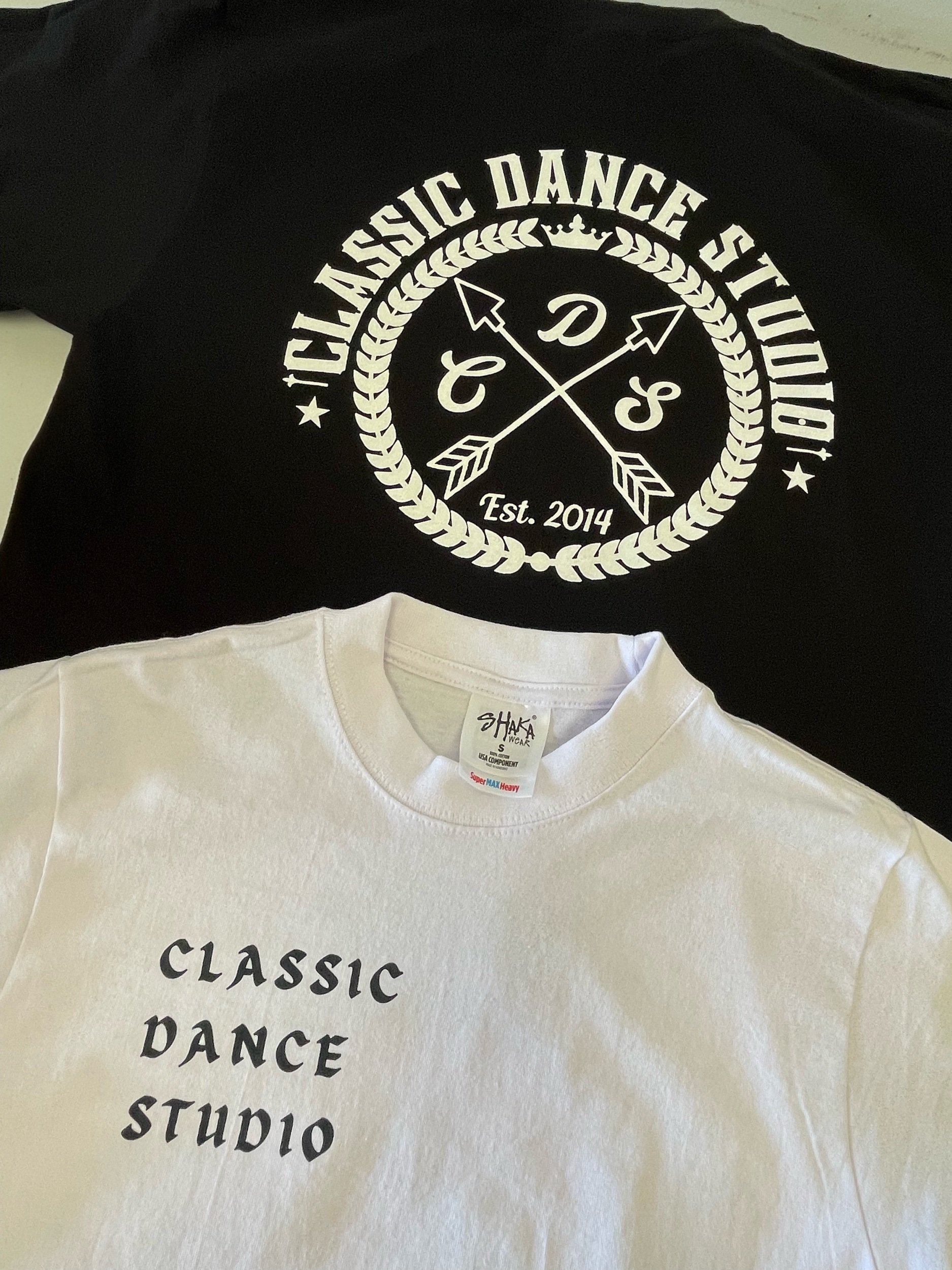

SCREEN PRINTING

Screen printing is the art of creating a stencil from a mesh screen and transferring ink through it onto an object. It’s the most common, efficient, and stable way to decorate a T-shirt. We can print a lot more than T-shirts though. Hoodies, Tank Tops, Tote Bags, Lanyards, Frisbees, Concert Posters… What do you need? We like a challenge!

INK OPTIONS

Each of our inks have unique qualities and produce a different product. Selecting the right ink for you print really depends on what you're going for.

PLASTISOL INK

Plastisol ink is a type of ink commonly used in screen printing. It's made up of PVC particles suspended in a plasticizing emulsion. When exposed to heat, the PVC particles fuse together, creating a durable and long-lasting print on the fabric.

Here are some key characteristics and advantages of plastisol ink:

Versatility: Plastisol ink can be used on various types of fabrics, including cotton, polyester, blends, and even some non-textile surfaces.

Opacity: Plastisol ink provides excellent opacity, making it suitable for printing on dark-colored garments without the need for an underbase.

Vibrant Colors: Plastisol ink offers a wide range of vibrant colors that retain their brightness even after multiple washes.

Durability: Once cured, plastisol ink forms a strong bond with the fabric, resulting in prints that are highly resistant to cracking, peeling, and fading.

Ease of Use: Plastisol ink is easy to work with and can be manipulated to achieve various effects, such as high-density prints, special effects, and textures.

Long Shelf Life: Unlike water-based inks, plastisol ink does not dry out when left unused, giving it a long shelf life and making it economical for large-scale production.

dISCHARGE INK

Discharge ink is a type of ink used in screen printing that is designed to remove or "discharge" the dye from the fabric it is printed on. It contains an activator that interacts with the dye in the fabric, breaking down its color and allowing the ink to replace it with a new color.

Here are some key characteristics and advantages of discharge ink:

-Soft Feel: Discharge ink produces prints with a soft hand feel because it essentially removes the dye from the fabric rather than adding a layer of ink on top.

-Vibrant Colors: Discharge ink can produce vibrant and opaque colors, especially on dark-colored garments, as it removes the existing dye and replaces it with the color of the ink.

-High Detail: Discharge ink is capable of achieving high levels of detail and sharpness in prints, making it suitable for intricate designs and fine lines.

-Long-Lasting Prints: Once properly cured, discharge prints are durable and long-lasting, with excellent wash fastness.

-Eco-Friendly: Discharge ink is considered more environmentally friendly than plastisol ink because it does not contain PVC or phthalates. However, some discharge inks may contain formaldehyde or other chemicals, so it's important to choose environmentally friendly formulations when possible.

-Versatility: Discharge ink can be used on various types of fabrics, including cotton, blends, and some types of polyester. However, the effectiveness of discharge ink may vary depending on the dye and fabric composition.

HSA INK

High-Solids Acrylic (HSA) ink in screen printing refers to a type of ink that contains a high concentration of solid pigments suspended in an acrylic resin base. This formulation results in a thicker ink consistency compared to traditional inks, as it contains less solvent and more pigment.

HSA inks offer several advantages in screen printing:

Vibrant Colors: The high concentration of pigments in HSA inks produces vibrant and opaque colors, even on dark or colored fabrics.

Excellent Coverage: Due to their high pigment content, HSA inks provide excellent coverage, minimizing the need for multiple print layers to achieve opacity.

Durability: HSA inks are known for their durability and resistance to fading, making them suitable for long-lasting prints, even after multiple washes.

Fast Drying: HSA inks typically have faster drying times compared to traditional solvent-based inks, which can help improve production efficiency.

Environmental Considerations: Many HSA inks are formulated to have low levels of volatile organic compounds (VOCs), making them environmentally friendly and compliant with regulations.